Important: The information presented here is for the use of a qualified, experienced technician. Without the background knowledge which comes with training, you risk doing more damage then good to the copier & also risk your own safety. If you are not willing to take 100% responsibility for your actions, do not use the information posted here. Thank you. Read our conditions of Use for more information.

DC250 style - Fault Code 042-326 : Belt Home Sensing Error

DC250 style - Fault Code 042-326 : Belt Home Sensing Error

| Technical Specifications |

|---|

DC250 style (DocuColor)DC240/242/250/252/260, DC5000, DCP700/700i/770, Fault Code 042-326 : Belt Home Sensing Error.

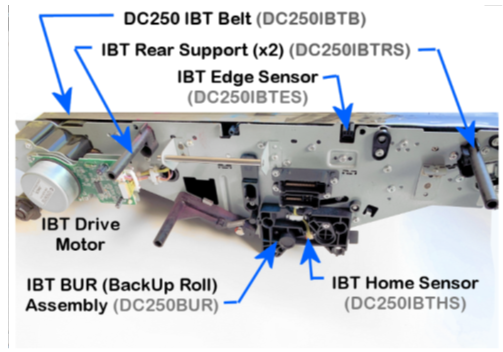

You will first want to take the IBT Belt Module out to check the IBT Belt for tears or other damage especially near the rear edge. To remove the IBT Belt Module requires first sliding the Main Transport Drawer (the drawer with the fuser and 2nd BTR assembly in it) all the way out to the service position. Slide the big drawer out until it stops and then press in the two release clips on the rails, releasing it out another 6 inches or so. That gives you enough room to slide the IBT Belt Module out far enough to lift it out of its cradle. If the belt has a tear in it, replace the IBT Belt (DC250IBTB). Clean the Home Sensor and the little square reflector located inside the belt near its rear edge (if the reflector is scratched up and not reflective, you can either replace the IBT Belt (DC250IBTB), or you can replace the little square reflective patch (it is available in a peel and stick sort of repair patch (DC250IBTRP). Also take notice if the belt has "walked" to the front or rear limits of the module. Normally it should be centered front to rear on the rollers.

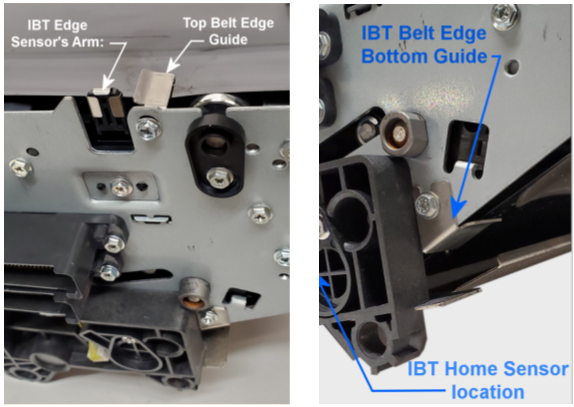

When you reassemble the IBT Belt Module you will want to make sure the Belt Edge Sensor is in position. It has an arm that should remain spring loaded against the edge of the IBT Belt... it is located near the top of the IBT Belt Module at the rear. If the edge sensor is damaged or its arm has gotten bent out of position (or if it is not calibrated properly - see below for how to do the "Belt Edge Learn" procedure to calibrate this sensor), the belt can walk far enough that the reflector inside the belt no longer lines up with the home sensor when it comes around and the fault code 042-326 results.

See the photo below for locations of the IBT Belt Home Sensor and the Edge Sensor:

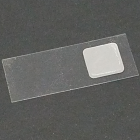

Another possible cause of the fault is if the rear edge of the IBT Belt is flared or "curled" away from the module. If it curls enough, the home sensor reflector patch inside the belt is not facing straight up at the sensor when the patch comes around, so the light reflects away at an angle and the sensor fails to see it. Xerox did come out with a cool kit for correcting that problem. There is an IBT Belt Anti-Curl Kit that adds a metal skid piece on the rear of the IBT Belt Module near the home sensor and also a second metal guide that is installed near the edge sensor. This keeps the belt from flaring in those two critical places (DC250IBTACK)

Here are a pair of photos showing what the Anti Curl Kit pieces look like when installed on the IBT module:

There are two things you need to do in diagnostics after everything is clean and in position... FIRST: Reset the Fault Code from NVM Read/Write ... This machine will lock-up and not run at all if it sees the Belt Home Sensor Error 3 times in a row. A memory setting needs to be reset back to "0" in NVM Read/Write in diagnostics before the machine will try moving the belt again. To reset the fault, go into maintenance/diagnostics and find NVM Read/Write. Then consult this list of models to see which NVM Chain-Link code to set back to "0": - For DC250, 7675, 7775 Families: NVM Chain Link Code = 741-105 (DocuColor) DC240, DC242, DC250, DC252, DC260, (WorkCentre) WC-7655, 7665, 7675, 7755, 7765, 7775: - For 550/C60/C9070: NVM Chain Link Code = 741-119 [(Color) 550/560/570, C60/C70, C9065/C9070] - For DCP700/700i/770: NVM Chain Link Code = 741-106 - For C75/J75: NVM Chain Link Code = 741-132

SECOND: Run the Belt Edge Learn procedure ... Any time you remove the belt module and reinstall it, it is a good idea to run the "Belt Edge Learn" procedure from the "Adjustments/Others" submenu in Maintenance/Diagnostics mode. You will line the IBT Belt up in the center of the rollers, then after resetting the fault code in NVM Read/Write.. When the machine is rebooting, keep the front door open so you can enter diagnostics mode without the machine completely setting up. Once you are in diagnostics, close the front door. Then find "Belt Edge Learn" and run that procedure to calibrate the machine to the sensor's position. The sensor is a rheostat. When its arm changes position, the resistance changes, telling the machine where the belt is, so it can turn on the steering motor and correct the belt's position if it starts to walk.

If a proper cleaning and resetting of the code does not solve the problem, you might need a new Belt Home Sensor (DC250IBTHS) or Belt Edge Sensor (D250IBTES). If the belt is walking out of the center when you check it again, suspect the edge sensor but if it is still in the center when the fault came up, that leans toward the IBT Home Sensor.

|