Important: The information presented here is for the use of a qualified, experienced technician. Without the background knowledge which comes with training, you risk doing more damage then good to the copier & also risk your own safety. If you are not willing to take 100% responsibility for your actions, do not use the information posted here. Thank you. Read our conditions of Use for more information.

V80-V280, & V2100-V4100 - IBT Belt Home Position Errors ( Fault 042-326)

V80/V2100 - Solving IBT Belt Home Sensor Faults (042-326)

| Technical Specifications |

|---|

Related Fault /Error Codes: 042-326 - Belt Home Position Too Long Fail - requires resetting from diagnostics after 3 occurences) 042-327 - Belt Position Fail - Belt Edge Sensor value out of range) 042-328 - Belt Edge Sensor Fail - Belt Edge Sensor value did not change during a full lap of the belt) IBT Home sensor errors can be caused by contamination of the Home Sensor or the little square reflective patch located inside the IBT belt near its front edge. The other common cause happens when the belt walks too far out of position and the Edge Sensor fails to detect that it moved. This is because if the belt walks far enough, the reflective patch will move out of range far enough to where the home sensor can no longer see it when it comes around. Remove the IBT Belt Module and check to see if the belt has migrated to the front or rear (it should normally be centered on the rollers from front to rear). If it is all the way to the front or rear, it might need the Belt Edge Sensor to be calibrated using "Belt Edge Learn" in diagnostics. Clean the reflective patch and inspect it to make sure it is not all scratched up (no longer reflective). If the patch is bad or missing you can replace just the patch (get a IBT Belt home sensor patch) or replace the IBT Belt. Also, clean the IBT Home Sensor (usually cleaning it is sufficient but you can also replace it as needed).

Component Control Codes (Dc330) relating to IBT Home sensing Input Codes (Sensors… L (low) = Paper Sensed, H = No Paper Sensed): 077-113 - IBT Home Sensor (put white paper under sensor… should change to “L” on screen) 042-041 - IBT Steering Motor (This motor changes position of the steering roller to help correct the position of the belt edge if the edge sensor sees it starts to walk).

Output Codes (Motors): 077-048: Inverter Drive Motor - Also check the motor’s wound resistance (should measure approx. 1.3 ohms) at P/J 246, pin 2 to pins 1 or 3, and pin 5 to pins 4 or 6. 077-052: Duplex Drive Motor - For V80/V180: V80DXDMA / 068K59342 OR For V2100/V3100: 049K21690) Also check the motor’s wound resistance (should measure approx.. 0.8 ohms) at P/J 266: pin 2 to pins 1 or 3, and pin 5 to pins 4 or 6.

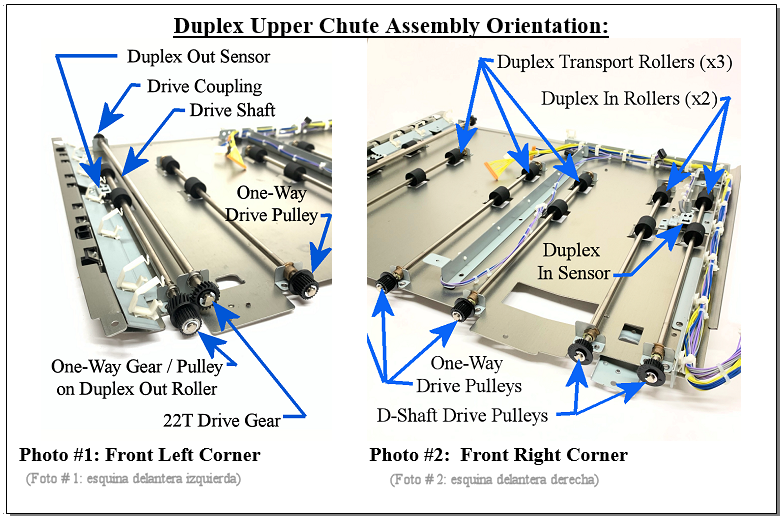

There are several areas that have parts relating to duplexing: - Duplex Lower Chute (6 pinch rollers with their springs) - Drive Motor Assembly (motor, gears and drive coupling) - Duplex Upper Chute Assembly (drive gears, one-way drive pulleys, and 6 transport rollers with their associated bearings) - Main Transport Drawer (idler pulleys & drive belt)

The Lower Chute Assembly is the metal plate that drops down to allow the customer to clear jams from the duplex area. The only parts on the Lower Chute of significance would be the 6 Pinch Roll Assemblies (hard plastic) and their retaining springs, which maintain nip pressure. If you find the paper is skewing in the duplex, you would want to check these pinch rolls to make sure they all spin easily enough (clean the plastic cradle bearings, check that they are not out of round from wear, and add a drop of silicon gear grease for lubrication). Also, check the tension springs are all providing similar pressure. If these Pinch Rollers don’t turn easily, they will add a lot more stress on the whole drive train, so checking and oiling them is an important first step.

The Duplex Drive Motor Assembly is seldom the cause of drive problems Although it can sometimes suffer from the extra strain put on it when the other duplex parts develop high resistance from wear and contamination. The motor has a part number on its label: 127K52720, although that number is invalid.

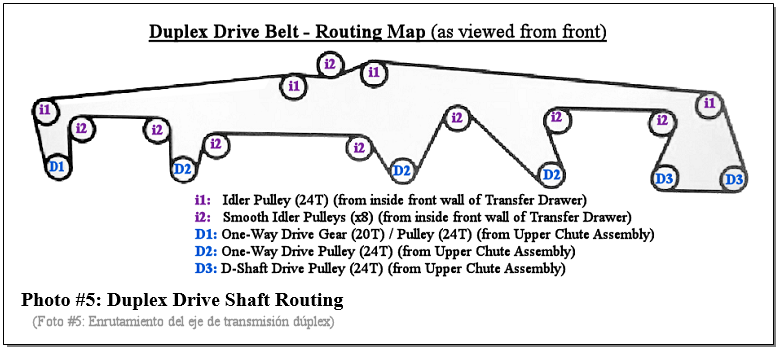

The Drive Assembly’s coupling drives a matching coupling on the rear of a shaft on the left side of the Duplex Upper Chute Assembly. The drive shaft reaches to the front of the unit, where you will find a 22-toothed D-Shaft Drive Gear, which mates up with a One-Way Drive Gear / Pulley (20T/24T) on the front end of the Duplex Out Roller (we sell the two gears in a Duplex Drive Gear Kit: (V80DXDGK). Then this piece drives the Duplex Drive Belt, which moves a series of one-way pulleys to turn the rest of the Duplex Rollers on the Upper Chute Assembly.

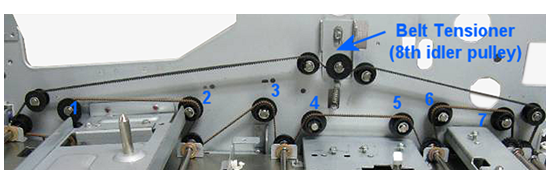

The Upper Chute Assembly is mounted under the Main Transport Drawer. The drive belt gets its tension from a series of Idler Pulleys (some toothless and some 24T) mounted on the inner front wall of the Main Transport Drawer.

Most duplex jamming problems stem from increasing friction (due to dirt and wear of the pulleys and bearings) and the subsequent failure of the one-way clutches (pin-bearings) found in the Drive Gear / Pulley and the 3 One-Way Pulleys. Getting to the Duplex Drive Belt and the Upper Chute Assembly takes a little bit of doing.

Removing the Duplex Drive Belt and Upper Chute Assembly:

- Pull the Main Transport Drawer (Transfer Drawer) out to the Service Position. - Remove the Drawer Front Covers: left cover (3 screws), Fuser Release Cover (2 screws), center cover (2 screws), right cover (2 screws), and the drawer handle (2 screws) - Lift the Fuser out - Remove the 2nd BTR Assembly: disconnect a connector and a high voltage lead, take off 2nd BTR front cover (1 screw), and then rock the unit towards the right to lift it out. - Remove the Registration Module: disconnect 4 connectors at front, remove 2 screws (one front left, one rear left), and remove the spring loaded guide pin near the front end of left rail (3 screws and rotate the spring / pin assembly (be careful as it is spring loaded). - Remove two metal brackets inside the front wall of Main Drawer: left bracket (3 screws), central bracket (2 screws). - Remove the Duplex Drive Belt Tension Pulley Bracket (1 screw). - Remove the Duplex Drive Belt, taking careful note of how it is routed (see Photo #1 below for the layout, as viewed from the front end) - At this point, getting the Upper Chute Assembly off is easy enough:

Here is a quick anatomy of the Duplex Upper Chute Assembly… The Duplex In Rollers (x2) on the right end of the Assembly are driven by ‘D’ shaft pulleys which don’t tend to wear out. Then the next 3 rollers we will call the “Duplex Transport Rollers.” Those 3 are all driven by One-Way Drive Pulleys. The one-way clutches in these pulleys can get weak over time and so should be replaced if the duplex is slipping. Similarly, the Drive Gear / Pulley on the front of the Duplex Out Roller (that is the roller on the far left) also has a one-way bearing which can start slipping. All three One-way Pulleys and the One-Way Drive Gear / Pulley should drive faithfully in the clockwise direction. If you suspect these are slipping, also check the front ends of the shafts where these pulleys are seated. Look for signs of the metal itself getting worn out (discoloration and a change of texture). Replace any Duplex Rolls which prove to be worn out in this way. The wearing only tends to happen if the one-way pulley has already failed and is slipping on the shaft, so catch it early if possible.

V80/V180 shown below in photos... (V2100 version looks different)

Note that there is also an Idler Pulley improvement kit that was introduced which has a set of toothless idler pulleys with a pair of ball bearings added to the centers of each. 655N00388 came with 7 idler pulleys, 14 flanged bearings, & 14 white o-rings. Strange because the kit seems to be one piece short. Then there’s 655N00588 which has only 5 idler pulleys, 10 bearings, and 10 O-rings.

We offer a few kits that address duplex jamming problems:

First... here are the parts for repairing the Duplex Upper Chute Assembly:

V80DXDGK - Duplex Drive Gear Kit:

V80DXDPK - Duplex Drive Pulley Kit: [x3 One-way Drive Pulleys & x2 D-shaft Drive Pulleys (499W14124)]

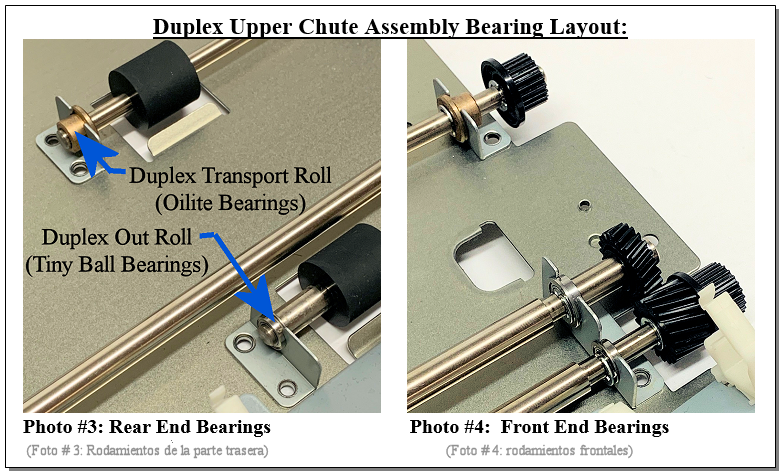

Also, check the bearings that the duplex transport rolls ride on (check these for being oblong and clean them and the transport roll shafts thoroughly… replace if needed). Note that the OEM V80 / V180 use plastic bearings, while the V2100/V3100/4100 use little flanged, metal ball bearings. For V80 / V180 / V280: Our kit below replaces the plastic bearings with oilite bearings. For V2100 / V3100 / V4100:

For the Idler Pulleys inside the front of the Main Transport Drawer... we offer two choices:

The cheaper choice is the original all-plastic pulleys (clean off the shafts good and add a drop of lubricant / gear oil on each pulley as you install them):

OR ... there is an improved version of these pulleys that each has a pair of ball bearings in the center of each pulley... This is recommended for a very long life, especially if you run the machine heavily:

Don’t forget the Drive Belt itself: (for V80/V180/V280):

Note: For V2100/V3100/V4100 there are two drive belts: 049K21690 drives 4 of the transport rollers and 423W80154 drives the Duplex In Roll and the first of the transport rollers. The transport rollers and pinch rolls do not have part numbers assigned in the V2100 parts books we have seen so far.

The following components fit the V80/V180/V280. It remains to be seen if the same rollers will work in the V2100. Eclip grooves might be positioned differently.

- Duplex In Rollers with plastic bearings (appears x2): (059K88060) - Duplex Transport Rollers with plastic bearings (appears x3): (059K88070) - Duplex Out Roller with tiny ball-bearings (appears x1): (059K88050) - Duplex Pinch Roll Kit with plastic bearings (appears x3): (059K88040) That just about covers both sides of it all! :)

|

| Information Reference |

Author: Britt Horvat This is one of our own Partsdrop Write-ups. We hope you find it helpful! |