Important: The information presented here is for the use of a qualified, experienced technician. Without the background knowledge which comes with training, you risk doing more damage then good to the copier & also risk your own safety. If you are not willing to take 100% responsibility for your actions, do not use the information posted here. Thank you. Read our conditions of Use for more information.

DC250 style - Direct Pipe Assembly Replacement Instructions

DC250 style - Direct Pipe Assembly Replacement Instructions

| Technical Specifications |

|---|

DC250 style (DocuColor)DC240/242/250/252/260, DCP700/700i/770, Replacing the Direct Pipe Assembly (Waste Auger Assembly)

Xerox deserves some serious kudos where their Service Manuals are concerned. For most of the decent sized machines, their books are truly impressive and very thorough. Every once-in-a-while though, you’ll run across something that you’re sure should be in the book somewhere, but it’s simply missing. In this case we’re going to look at one such missing piece of info. Each family in the DC250 style has its own Service Manuals, and in none of them will you find a REP (Repair Procedure) dedicated to removing the Direct Pipe Assembly. I figured this meant it’d be straight forward… but it turns out it's not all that easy to remove. It really deserves some instructions. The Direct Pipe Assembly is the assembly which has a series of augers which transport the waste toner away from the drum cartridges, developer units, and also the IBT cleaning assembly. The assembly moves the waste toner through tubes with augers toward the Toner Waste Container. There are two versions, each of which has a few valid part numbers. The two versions are extremely similar but they’re not interchangeable because the metal mounting bracket is different.

DC250 version: (Part Numbers: DC250DPA, 049k06530, 068K24134, 068K24/136, 068K24137, 049k27440)

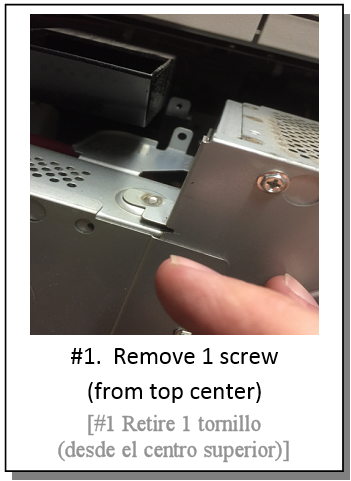

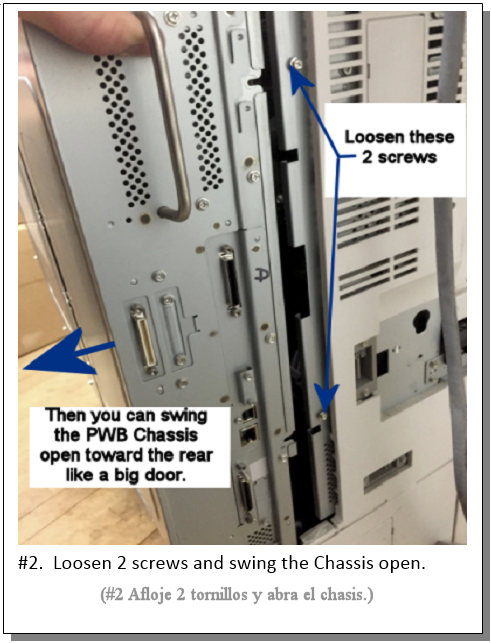

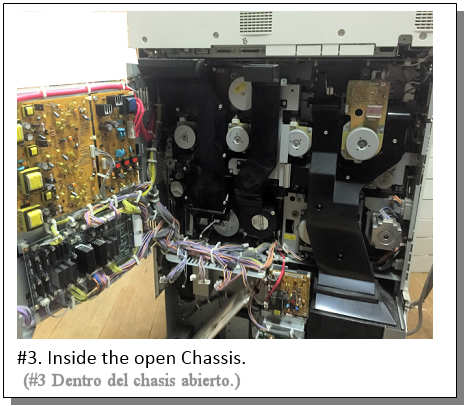

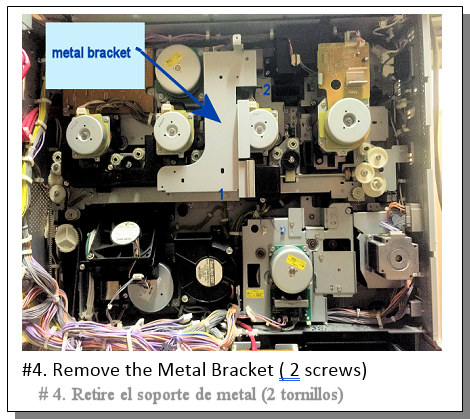

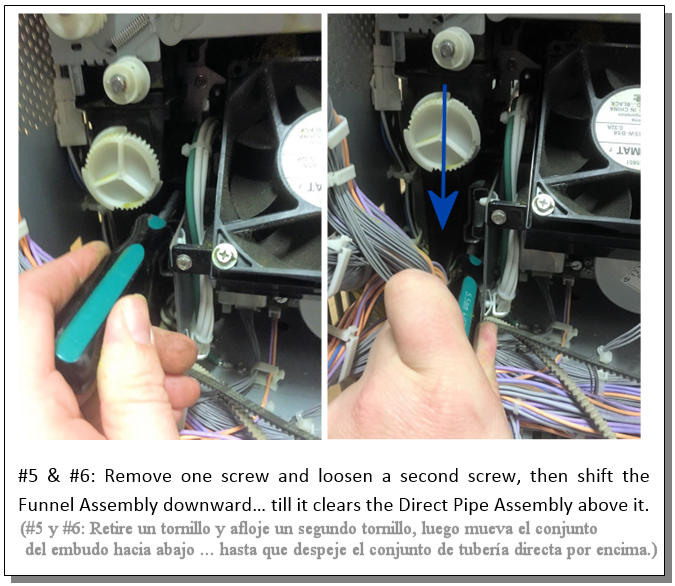

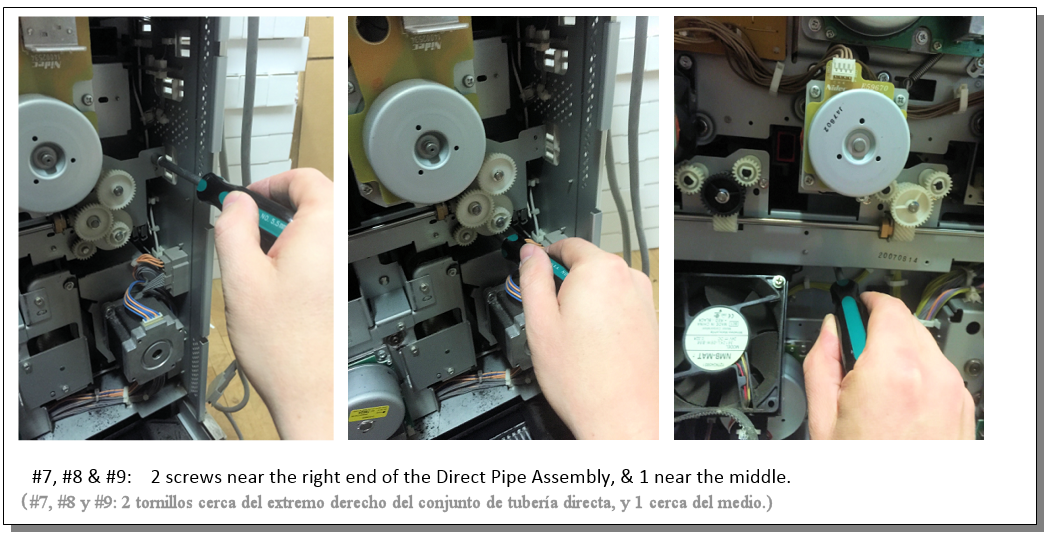

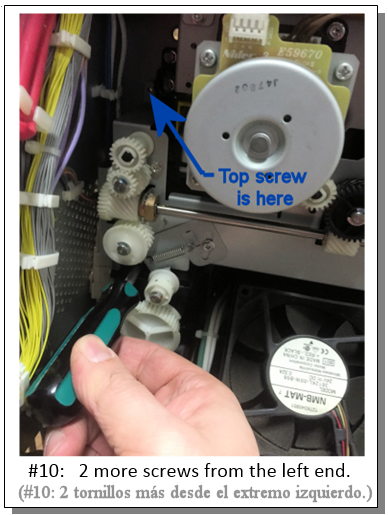

DC700 version: (Part Numbers: 052K13211, 052K13210, 052K96750, 052K96752) (fits these models: DCP700, DCP770, C75, J75) Symptoms of a clogged or broken Direct Pipe Assembly can take a number of possible forms. Sometimes it’s popping noises as the angled gear (DC250DPG1) starts slipping past the gear on the long drive shaft. Other times the noise goes unnoticed and the machine starts throwing xxx-xxx fault codes because the Main Drives get bogged enough for the machine to detect that something isn’t turning right. Another common symptom is a relatively large amount of toner spilling out from behind drum cartridges or the IBT Cleaning Assembly. Now let’s see how to get this messy thing out of the machine: PROCEDURE:

Once all those screws are out… you can very gently work the Direct Pipe Assembly out of its place. It is fairly tight, (end to end especially) so take your time and be patient. When installing the new one, make sure to check carefully that it's fully seated in all its ports and all brackets on the unit are flush with the frame. Don't forget to raise the Funnel Assembly back up to engage the Direct Pipe Assembly again, and return its screws to their positions so it can’t drop back down later during operation.

Now, there is also the matter of “why did this thing get clogged up and break in the first place ???" The most common cause is if the Toner Waste Bottle is not fully pushed in, the toner can clog going into the bottle and then it backs up into the waste augers and stuff starts to break. Other factors can be clumpy toner. If toner is fused by heat inside the toner cartridge to form beads of hard grit, those little toner rocks can clog up the system (leaving a toner cartridge in a hot car has been known to do this for example). Also we’ve seen that some aftermarket toners do not flow as nicely as the OEM product, so it may bind-up, especially if it gets a lot of moisture. What if you find that cleaning it out and replacing just the angled gear would do the trick? If so, you can find an aftermarket gear is available (DC250DPG1) but the OEM part lists don’t assign this gear a part number as they spare the gears only as part of the complete assembly.

There you go… we just filled in one of the few blanks in the DC250 Service Manuals. |

| Information Reference |

Author: Britt Horvat, with special thanks to Kurt for his expertise and thanks also for support from whole Partsdrop gang. Originally published as an Article in the marvelous ENX Magazine - www.enxmag.com :) All rights reserved... you can distribute copies as long as you include a link to the source website: www.partsdrop.com |