Important: The information presented here is for the use of a qualified, experienced technician. Without the background knowledge which comes with training, you risk doing more damage then good to the copier & also risk your own safety. If you are not willing to take 100% responsibility for your actions, do not use the information posted here. Thank you. Read our conditions of Use for more information.

7120, 7125, 7220, 7225 - Drum Cartridge Rebuild Instructions

| Technical Specifications |

|---|

Xerox 7120 style Drum Cartridges… Repairing and rebuilding the Drum Cartridges for the WC-7120, 7125, 7220, 7225

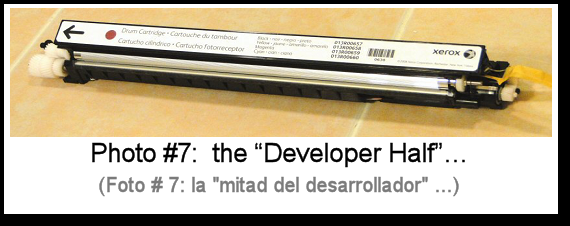

The WorkCentre 7120 style continues to prove itself as a popular series. We took on the fusers a few months back and now it’s time to have a look at the Drum Cartridges. We’ll take one apart and see what makes it tick. Especially important is how to replace the Drum Reset CRUM chip which resets the counter. This is how you can maximize the yield on the cartridge if it is still making good copies when it times out. These machines use 4 Drum Cartridges which are referred to as “Smart Kits”. There is one for each color position: Black = 013R00657, Yellow = 013R00658, Magenta = 013R00659, & Cyan = 013R660. These drum cartridges include the Drum, Charge Roll, and Drum Cleaning section in one half of the cartridge, and a Developer station on the other half of the cartridge (thus the necessity of having 4 different cartridges so the right color developer is in each). The Drums, Blades, Charge Rolls, Charge Cleaning Rolls are all the same in each color cartridge… but the Drum Reset CRUM chip is unique to each color. The stated yield for these drum cartridges is 51K pages for the color drum ctgs and 64K pages for the black drum cartridge. So far… as of the publishing time of this article, we have seen Drums and CRUMs already available, but nothing else yet… but that is likely to change over the next few months as the demand for drum cartridge parts increases. The fact that there is a developer station on the cartridge makes it a trickier cartridge to tackle. Eventually parts distributors will need to find replacement developer and seals as well as all of the other parts involved in rebuilding one of these guys. Let’s get into the disassembly of the cartridge. We’ll start by going far enough to replace the CRUM chip which is needed to reset the drum count for the machine. Then we’ll go further into it and replace the drum, charge roll, cleaning roll and cleaning blade. The Developer half of the unit will have to wait for a future article when more information and materials are available.

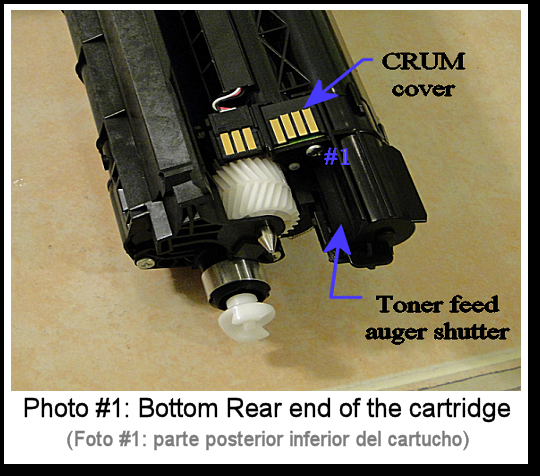

You will find the Drum Reset CRUM on the rear end underneath the drum cartridge. Remember each color drum cartridge has its own unique CRUM (they’re not interchangeable), so order the correct one.

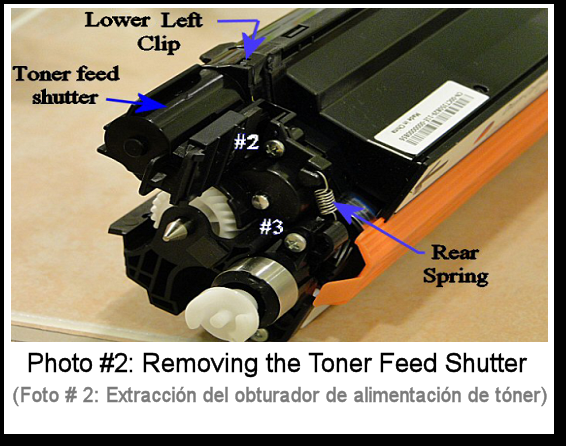

1.) To get to the CRUM, you will first need to remove the Toner Feed Shutter. Take off 3 screws (see photos 1 & 2). Also remove the rear spring which helps keep the two halves of the cartridge together. Finally there is a very stubborn clip in the lower left corner of the Toner Feed Shutter (if you have the cartridge flipped over with the CRUM facing up as shown in Photo #1, the clip is on your right). The way the clip is built around a corner piece, makes it seem like it may be necessary to break part of the clip in order to release it. Our example cartridge’s clip was broken in the process of trying to release it, and we found that even so, the clip still seated and with the 3 screws to hold it, it was of no consequence that the clip broke.

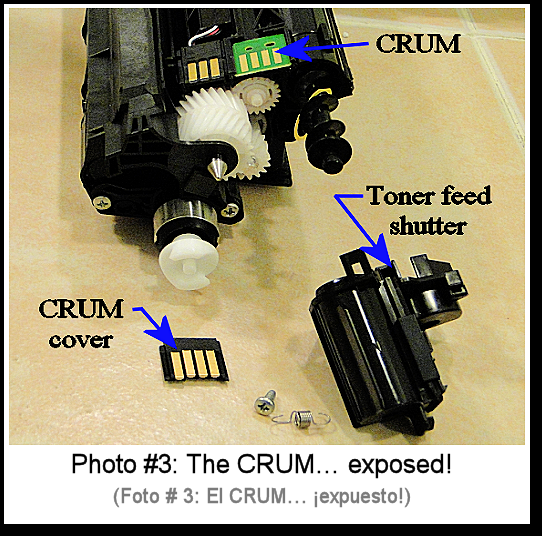

2.) With the Shutter out of the way, you can slide the black plastic CRUM cover off towards the rear (it is a black piece with 4 gold contact points… see photo #3). Then the CRUM will slide off easily enough.

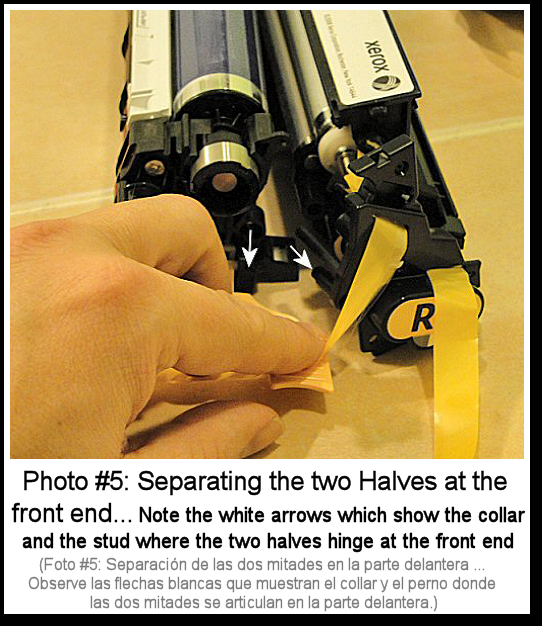

3.) Next we’ll go the front end of the cartridge to get ready to separate the Developer Half of the cartridge from the Drum Half. Remove 2 screws from the front cover of the developer housing half (See Photo # 4, where it says “R3” (R3 is the Magenta cartridge which is what we used for this write up… yours might say “R1, 2, 3, or 4” depending on which color drum ctg you’re working on). Also remove one spring and finally release 2 clips (one at the top right and one at the lower right corner). CAREFUL! When you extract this cover, it releases the Developer half of the cartridge from the Drum Half on the front end (see Photo #5), and if you then slide the Developer Half forward towards you, it will unseat from the Drum Half at the rear end where the main drive gear shaft seats into a. Be careful because all of the gears on the Developer Half can fall right off of their shafts at this point.

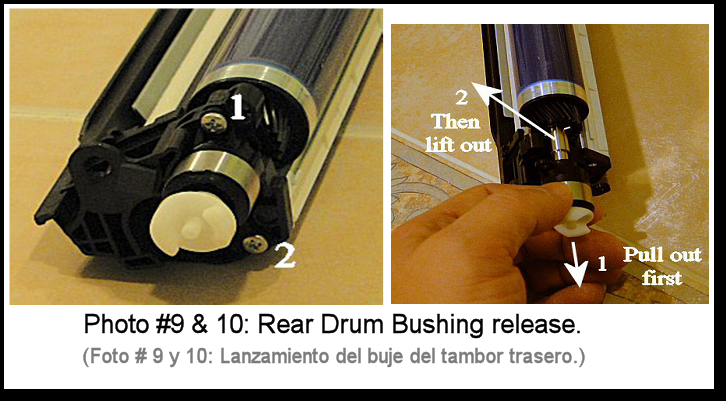

4.) Now we’ll concentrate on the “Drum Half” of the cartridge (see Photo #6). Pull firmly on the Front Drum Bushing (see Photo #8)… it is the piece with the silver band around it). It is held by a pair of anchor hooks but if you pull firmaly and rock it a little, it will unseat without too much of a fight. (take note of where the 2 anchors were located so you can reassemble it easily later). Next go the rear of the drum. Remove 2 screws from the rear end to release the rear Drum Bushing / Shaft (see Photo #9 & 10)… it will slide out a bit giving room for the drum to lift out of the rear end cradle. Lift the Drum out.

5.) With the drum out of the unit, you can remove the Drum Cleaning Blade (2 screws) and clean the waste toner auger behind the blade carefully (be very gentle with the mylar Recovery).

6.) You can now lift the Charge Roller out (avoid touching the surface of that roll… finger prints will cause copy quality problems). The black cradle / contact for the charge Roll is conductive plastic and it can use a little conductive grease. You can lift it out to help you get the Cleaning Roll out of the unit as well. There’s a “Discharge Lamp” which in truth is just a light-bar which gets illuminated by an LED in the machine.

We’ll need to look closer at the Developer Half sometime in the future… when replacement developer and seals for the Developer charge compartment become available. When a new cartridge is installed, there are seals which are extracted from the front end by the customer (since my sample cartridge was actually a new cartridge you can see the yellow seals present in the photos). One of the pull seals releases the shot of developer so it can drop down into the chamber behind the Developer Mag Roller, and a second seal drops a small charge of toner to start the feed auger out, so it doesn’t take too long for toner to find its way to the developer mixing area of the unit.

Until replacement seals are available, shipping a cartridge would not work because the developer would get everywhere… This procedure is only useful for “on-site” or “hand deliver” situations. Happy Reconditioning!

|

| Information Reference |

Author: Britt Horvat, with special thanks to Kurt for his expertise and thanks also for support from whole Partsdrop gang. Originally published as an Article in the marvelous ENX Magazine - www.enxmag.com :) All rights reserved... you can distribute copies as long as you include a link to the source website: www.partsdrop.com |