Important: The information presented here is for the use of a qualified, experienced technician. Without the background knowledge which comes with training, you risk doing more damage then good to the copier & also risk your own safety. If you are not willing to take 100% responsibility for your actions, do not use the information posted here. Thank you. Read our conditions of Use for more information.

WC-5945 & B8090 Family - Fuser Module Rebuild Instructions

Rebuild the fusers for the WC-5945, 5955

| Technical Specifications |

|---|

For Xerox® models: (WorkCentre) WC-5945, 5955, & (AltaLink) B8090, B8075, B8065, B8055, B8045

Last month we took a peek at the Drum Cartridges (imaging units) for the brand new WorkCentre 5945 style. I like the looks of these new models so I was curious about the consumables. Now let’s have a shot at the Fuser Modules.

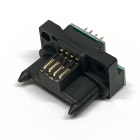

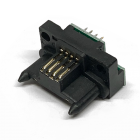

The WC-5945 / 5955 Fuser Modules are sold under the part number 109R00847 in the U.S. (110 Volts) or 109R00848 in European markets (220 Volts). According to the brochure, this fuser is rated for a stated yield of 250K. The lower speed models in the series (B8045 / B8055) use the same fuser (same part# as the 5945 as mentioned above). The higher speed models use a different part number: 109R00850 (110 volts) or 109R00851 in European markets (220 volts). . I have to admit I was originally lured into taking a closer look at this fuser because from the outside, many of the parts “looked” familiar. I hoped I would find that some of the parts were already available. Well, looks can be deceiving. Very few parts in this fuser are available as of yet…although I’m certain this will change with time. The Heat Roll looked familiar at first glance, but it is not like any earlier heat rolls we have seen. Also the picker fingers looked like those found in a much older model (think circa 1990 with the analog copier models 1012, 5011, 5012, & 5014)… but again they did not prove to be the same, in spite of being the same basic design idea. The one thing which was very nice is that the CRUM chip is already available (5945FCN). So the fuser count can be reset easily by replacing just the CRUM chip. This CRUM chip is easy to get to too… mounted right on the outside of the fuser with one screw.

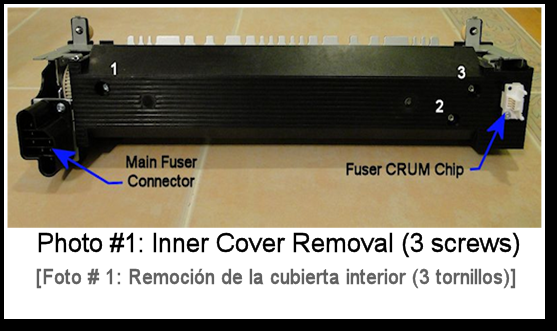

Let’s get right into the procedure starting with the location of the Fuser CRUM chip (Customer Replaceable Unit Monitor). It can be found mounted to the “Inner Face” of the fuser by one screw… piece of cake. This piece tells the machine which version of fuser it is (110 volt vs. 220 volt) and the machine “counts” on the CRUM chip… keeping track of the copy count which the fuser has used so far.

PROCEDURE:

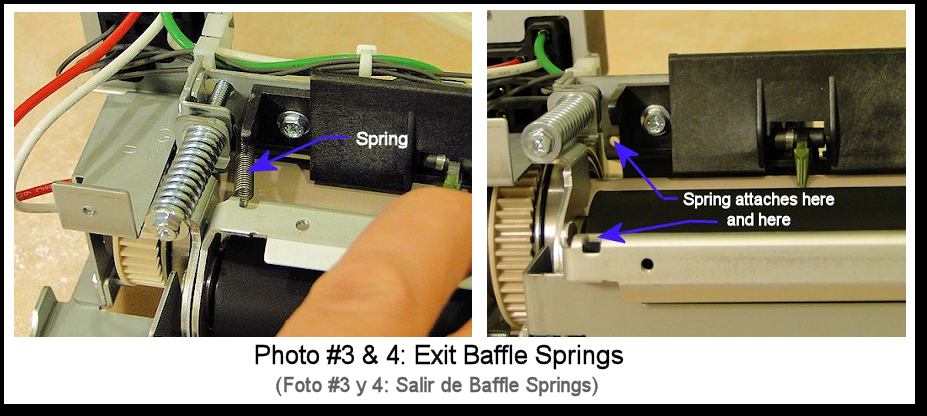

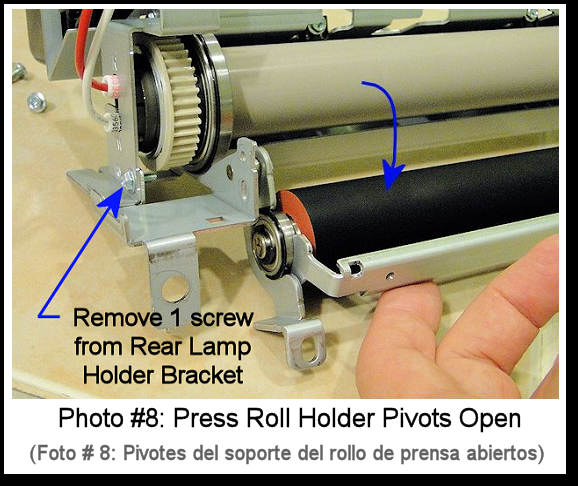

5. The Exit Baffle has a pair of pull springs (one at either end) which work to keep the baffle closed. Use a spring hook to release the springs (first take note where they hook in because it’s not that obvious later… see photo #’s 3 & 4). Once the springs are off, you can pivot the baffle away from the heat roll and the picker fingers. You’ll want to pay attention from this point on… taking care not to allow this metal baffle to flip back against the heat roll as it could cause damage.

Nicely done!

|

| Information Reference |

Author: Britt Horvat, with special thanks to Kurt for his expertise and thanks also for support from whole Partsdrop gang. Originally published as an Article in the marvelous ENX Magazine - www.enxmag.com :) All rights reserved... you can distribute copies as long as you include a link to the source website: www.partsdrop.com |