Important: The information presented here is for the use of a qualified, experienced technician. Without the background knowledge which comes with training, you risk doing more damage then good to the copier & also risk your own safety. If you are not willing to take 100% responsibility for your actions, do not use the information posted here. Thank you. Read our conditions of Use for more information.

WC-4150, 4250, 4260, 4265 Drum Cartridge Rebuild Instructions

| Technical Specifications |

|---|

For Xerox® models: (WorkCentre) WC-4150, 4250, 4260, & 4265

The 4150 style started with just one model, which was later joined by the 4250/4260. Now there’s a newcomer to the family: the WorkCentre 4265. All of these machines bring compact speed to the office environment… boasting speeds of 50-55 pages per minute desktop sized monochrome multifunction copier / printer. Extending the life of the Drum Cartridges is a major part of keeping the cost down to help assure that these machines remain profitable members of the fleet. We took the upper half of these cartridges apart in an ENX article 6 years ago (Dec. 2008) and learned how to replace the Drum, Blade, & Charge Roll, but two new developments in this series warrant a re-write. First let’s introduce the brand new 4265 model and look at what’s changed on the newest version. Second, good replacement Developer has only recently become available for this series. So, we’ll have to expand the older article to include info on how to replace the Developer material and the DV Pull Seal on the lower half of the cartridge. It will finally be possible to truly and completely rebuild these cartridges.

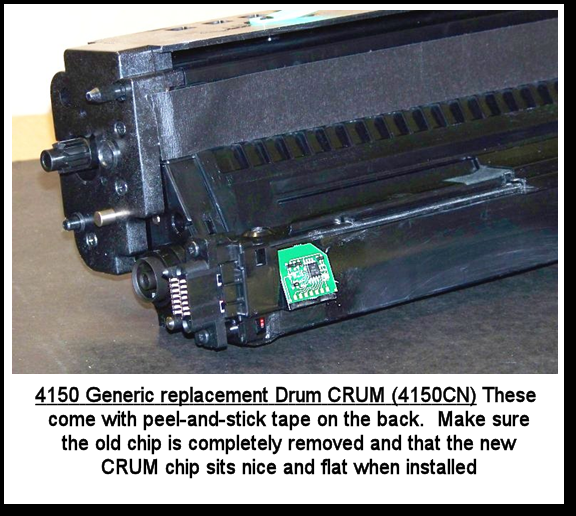

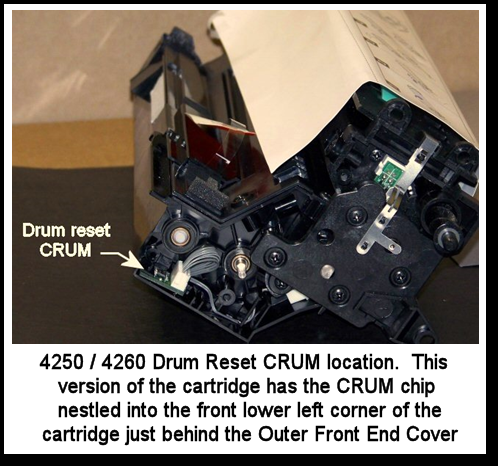

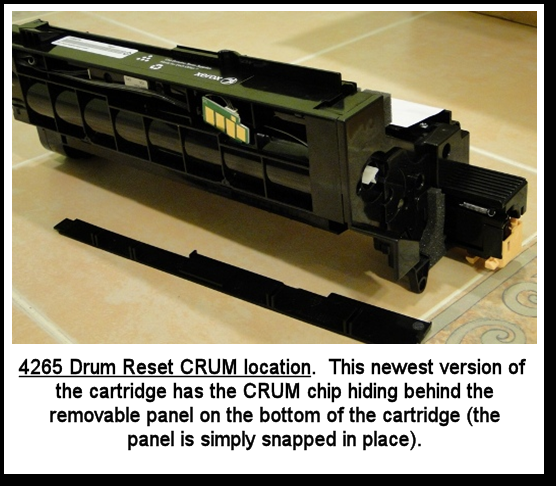

There are 3 generations / versions of these cartridges which for a few reasons are not interchangeable. The main difference is that the Drum Reset CRUM Chips have changed completely from version to version. See photos and read-up on the differences as they are detailed at the end of this article. Other subtler differences are noted in the text of the procedure.

Below are the 3 “Versions” of Drum Cartridges (or “Smart Kits” as Xerox likes to call ‘em):

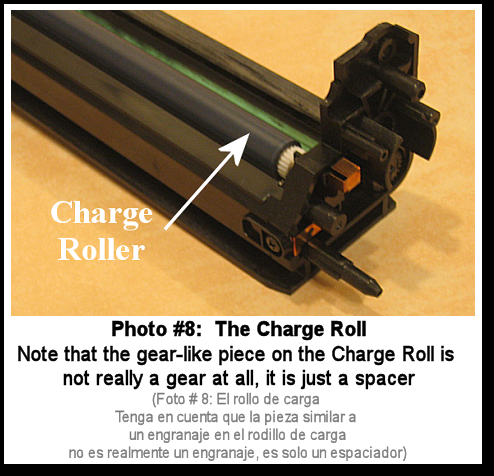

These cartridges include two basic halves… the top portion houses the Drum, Charge Roll, Cleaning Blade & Waste Toner Auger. The lower half is the Developer Housing. This cartridge is dual-component, so as you’ll see, it does have Developer and a mag roll.

Lets see how these come apart!

1. Start by removing the Top Rear End Cover (see Photo #1) (4 screws from the rear) and then you’ll need to do a little wiggling from side to side to work the cover off.

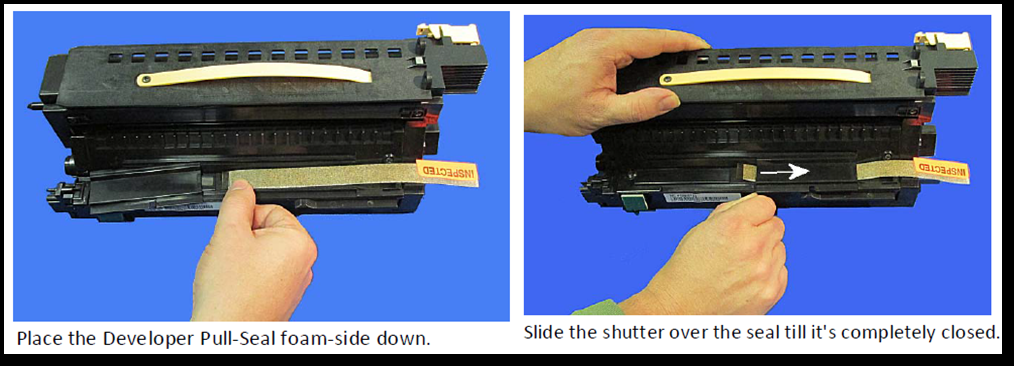

2. Next remove the Outer Front End Cover. Two screws come out from the front and then you’ll release a single hook at the top right, where it sticks through to just above the drum. There’s a small paddle gear which pulls off of its ‘D’ shaft (it’ll fall right off now, see Photo #2).

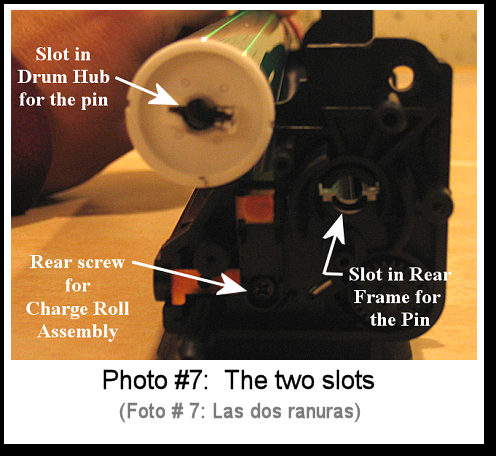

3. Then remove the Inner Front End Plate (see Photos #3 & #4). 4 screws from the front end.

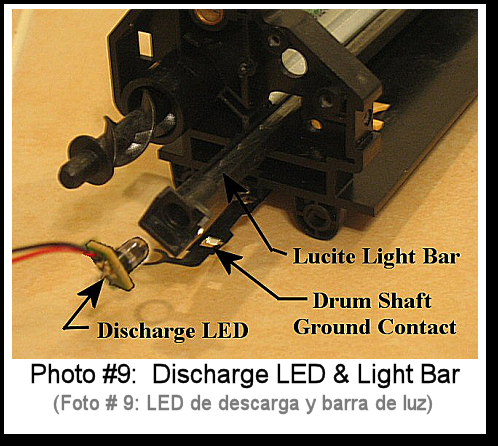

4. Now for the “big moment”… you will separate the Upper (drum) half and the Lower (developer) half. Start by disconnecting the white connector for the Discharge LED which is tucked into an alcove low down on the front end. Then the entire top half of the cartridge can hinge up to the right (see Photo #5)… Now shimmy it backwards off its hinge pins and lift it on off of there.

8. With the Discharge Light Bar out of your way, the Drum Cleaning Blade can be removed and replaced (4150DB) (2 screws).

11. Pour the new shot of developer into the stirring area and turn the stirring paddle & mag roll by hand (use a flat headed screwdriver to turn the coupling on the rear of the cartridge in the process direction which is counterclockwise). Do not overfill the cartridge. The white auger on the left side of the cartridge should not be covered past half way with developer.

12. Reassemble everything, and replace the Drum Reset CRUM (Customer Replaceable Unit Monitor). For the location of the CRUMs, see the photos and info below.

Happy Reconditioning in 2016 everyone!

|

| Information Reference |

Author: Britt Horvat, with special thanks to Kurt for his expertise and thanks also for support from whole Partsdrop gang. Originally published as an Article in the marvelous ENX Magazine - www.enxmag.com :) All rights reserved... you can distribute copies as long as you include a link to the source website: www.partsdrop.com |